WERIT Kunststoffwerke

WERIT – We are it!

Your Partner in plastic solutions

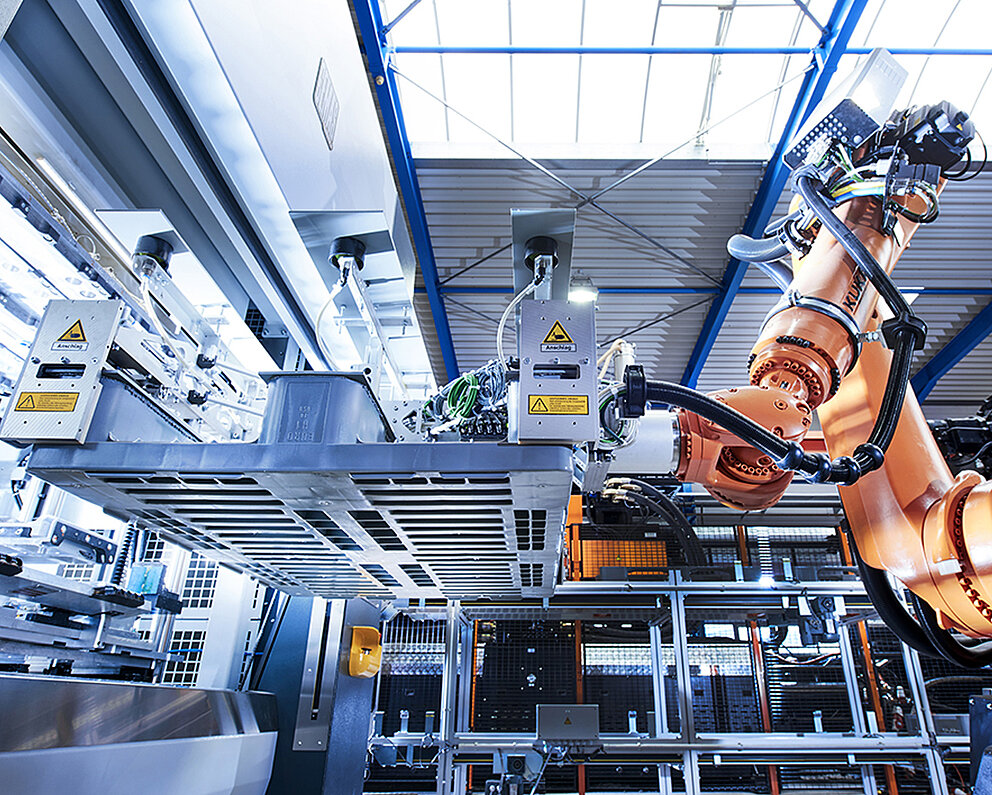

Bei WERIT produzieren rund 600 Mitarbeiter – an elf Standorten in ganz Europa – neue wie auch rekonditionierbare Industrieverpackungen sowie innovative Kunststoffprodukte. Durch die flexiblen und verschiedenartigen Anwendungs- und Kombinationsmöglichkeiten bietet das Unternehmen mit Stammsitz im rheinland-pfälzischen Altenkirchen (Westerwald) eine große Bandbreite an Individual-Lösungen für verschiedene Branchen an. Die Erfolgsgeschichte der Unternehmensgruppe WERIT begann bereits im Jahre 1949.

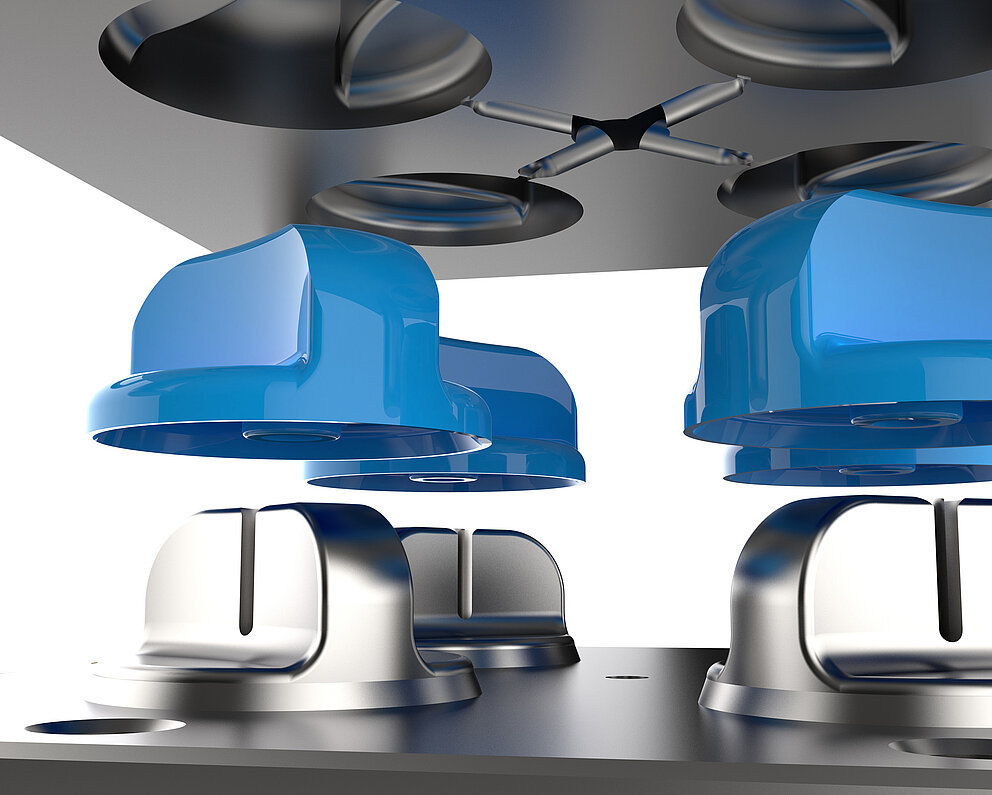

Zum Produktangebot gehören neben unterschiedlichen Mehrweg-Transport-Verpackungen (u.a. Stapelkästen, Eurobox mit Deckel) auch Industriepaletten sowie EURO H1 Hygienepalette, Industrie- und Heizöltanks, Regenwassertonnen und IBC Behälter nebst Zubehör. Des Weiteren ergänzen Schwallwasserbehälter, Auffangwannen und andere Kunststoffbehälter das Sortiment, das für branchenübergreifende Kernanforderungen ebenso geeignet ist wie für den spezifischen Bedarf, wie Bäckerkörbe, E1-Kisten, E2-Kisten und E-3-Kisten.

Begonnen hat es 1949 mit dem Erwerb der ersten Kunststoff-Bakelit-Pressen und der Produktion von Elektro-Verbindungsklemmen. Es folgten Spritzguss-Werkzeuge und die Produktion von Kunststoff-Spülkästen und einige Jahre später bereits Flaschenkästen. Anschließend der Bau der bis heute größten Blas-Extrusionsmaschine für Kunststofftanks mit einem Füllvolumen von über 5.000 Liter und bereits Ende der 70er Jahre die Produktion der 1.000 Liter Container auf Palette.

Dies war der Grundstein für die heutige Produktpalette von WERIT.

Das europäische Unternehmen mit rund 600 Mitarbeitern und Mitarbeiterinnen, sechs Fertigungs- und fünf Vertriebsstandorten produziert Produkte für die Haustechnik wie beispielsweise Heizöltanks und Spülkästen, Industrieverpackungen wie Palettencontainer, Kunststoffpaletten und -behälter sowie einige Spezialprodukte.

WERIT feiert 2024 ihr 75 Jähriges Firmenjubiläum. Gemeinsam mit den Jubilaren, die bereits 25, 40 und 45 Jahre für das Unternehmen tätig sind, blickt man auf viele erfolgreiche Jahre zurück und freut sich auf die weitere Zukunft. Das europaweit aufgestellte Familienunternehmen ist stolz auf seine Mitarbeiter und die gemeinsame Historie des Unternehmens. Das hohe Know-how der langjährigen Mitarbeiter sowie eine gezielte Aus- und Weiterbildung sichern das hohe Niveau der Fachkräfte auch in Zukunft. WERIT möchte auch weiterhin ressourcenschonende Produktkonzepte realisieren und eine starke Marke aufbauen. Die Weiterentwicklung bestehender Produkte steht dabei klar im Fokus. Der Gründer Dr. Helmhold Schneider, die Familie – gleichzeitig Gesellschafter des Unternehmens – verbinden wirtschaftlichen Erfolg mit gesellschaftlicher Verantwortung. „Das Unternehmen befinde sich beständig im Wandel“, so die Unternehmer. „Als Familienunternehmen denken wir nicht in Quartalen, sondern in Generationen – auch zukünftig.“

WERIT ist stolz auf seine Firmenkultur. Die Gesellschafter gratulieren den Jubilaren zu Ihrem 25- und 40-jährigem Jubiläum und bedanken sich ganz herzlich für die gemeinsamen Jahre.

Die Qualität der Prozesse und Erzeugnisse ist einer der entscheidenden Wettbewerbsfaktoren. Den zentralen Anspruch bildet dabei die konsequente Orientierung am Kunden, dessen Anforderungen unser Maßstab sind.

Als europäische Unternehmensgruppe setzt WERIT durchgängig ein zertifiziertes Qualitätsmanagementsystem ein. Dies ist nicht nur ein Qualitätsstempel, sondern sorgt für effiziente sichere Resultate, die sich abteilungs- und standortübergreifend widerspiegeln.

Hinweisgebermeldestelle

Die zur Verfügung stehenden Meldekanäle finden Sie im Impressum aufgelistet.

Newsroom

Neues rund um WERIT

Energieeffizienz ist Kosteneffizienz

Unser Projekt „Energetische Optimierung der Produktion" wird von der Europäischen Union aus dem Europäischen Fonds für regionale Entwicklung gefördert. Lesen Sie hier mehr dazu!